Technical data of the biodiesel fuel facility

The aim of the facility was to process all kinds of vegetable oils and animal fats as well as collected waste vegetable oil (UVUC) for biodiesel production. The biodiesel plant can convert vegetable oil or waste vegetable oil or vegetable fats into FAME (Fatty acids methyl ester) called Biodiesel. FAMEs (Fatty Acid Methyl Esters) are the main product. The quality of FAME is in accordance with EN 14214. Some fuel parameters such as CFPP (cold filter plug point), oxidation stability, phosphorus and sulphur content, iodine figure and fatty acid distribution depend on the quality of the feedstock and cannot be influenced by the process.

Facility Capacity:

4.000 tonnes of biodiesel / year

The system consists of a biodiesel reactor and 2 sedimentation tanks, biodiesel glycerine. These include metering pumps, attenuators, pneumatic valves and sensors.

Operating time of the installation:

The plant can operate 330 days a year continuously with semi-automation and full automation as a future option.

The reaction:

Oil + Methanol + (Potassium / Sodium Hydroxide) ->

Fatty acid methyl esters + Glycerol (equilibrium reaction)

Secondary reactions:

Free Fatty Acids + Potassium Hydroxide -> Soap + Water (equilibrium reaction) Neutralisation of waste washing water

Glycerol purification by distillation methanol extraction (future option)

Trans-esterification of triglyceride oils and fats with monohydric alcohols to form biodiesel largely eliminates the tendency of oils and fats to undergo polymerization and auto-oxidation and also reduces the viscosity of oil to one approximately equal to that of petroleum diesel.

The European standard for biodiesel is EN 14214. The German standard DIN E 51606 indicates three varieties of biodiesel, depending on the feedstock:

- RME (rapeseed methyl ester)

- PME (purely [vegetable] methyl ester)

- FME (fat methyl ester)

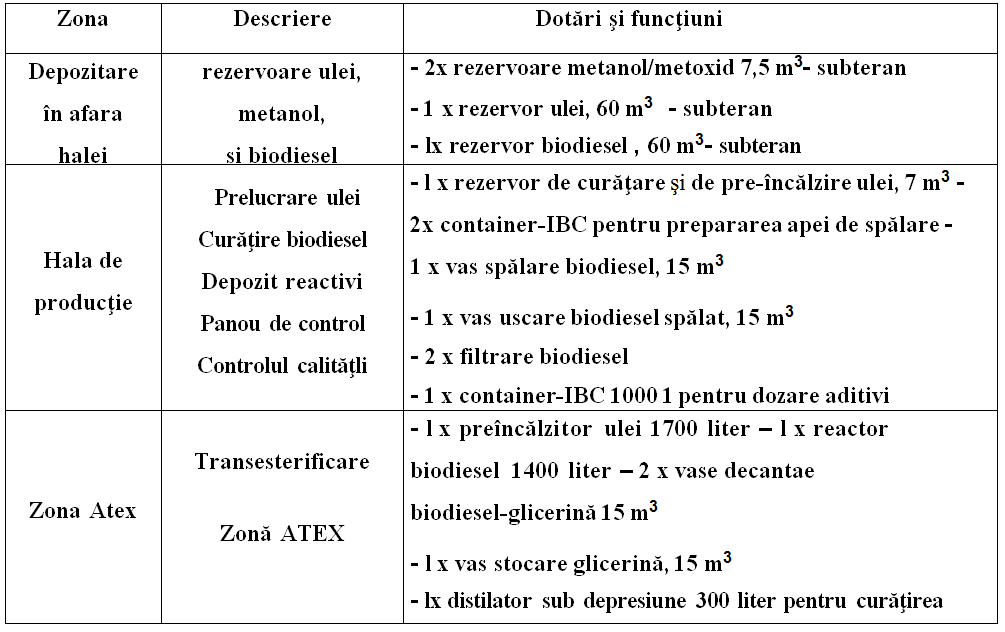

Functional areas and equipment of the biodiesel facility